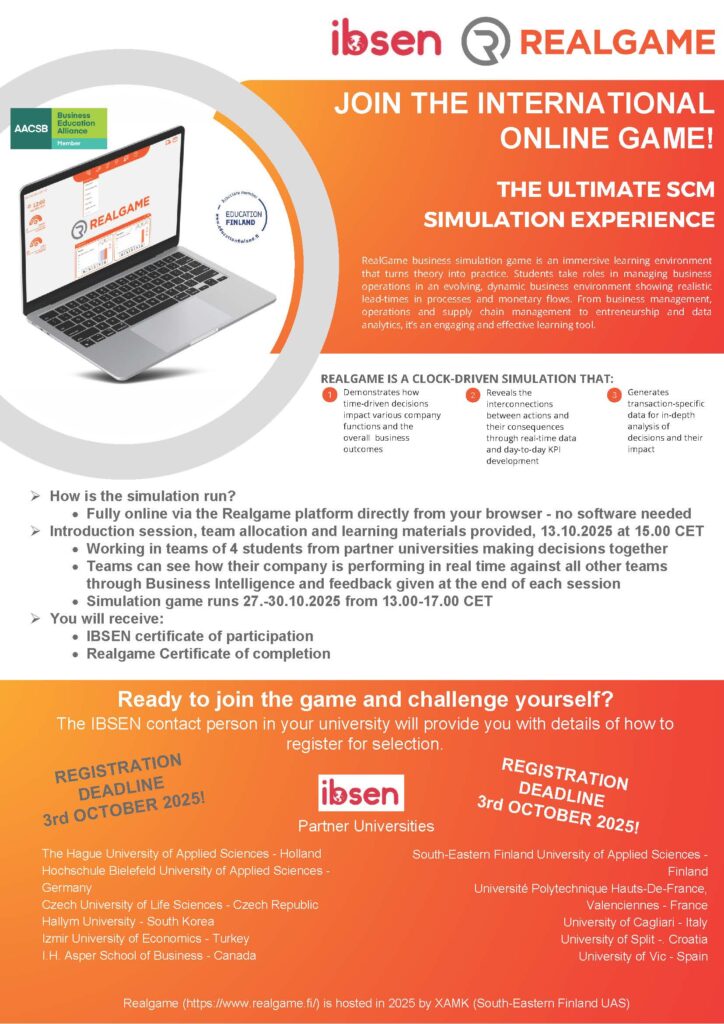

In October this year, students from IBSEN (International Business Studies Exchange Network) partners took part in a pilot project playing the Realgame business simulation online. This is the first time Xamk has run such an online international simulation, although more than 20 years ago – as Kyamk – we used to participate in an international business game that took place in different parts of the world each year. In those days students would form teams from partner universities, and play the game in MS Excel during an intensive two weeks.

This pilot project came about as a way to further development and cooperation in the IBSEN network – a network of twelve universities from Germany, Czech Republic, Netherlands, South Korea, Turkey, France, Italy, Canada, USA, Croatia, Spain, and of course, Finland.

The online sessions took place 27-30.10.2025, from 13-17:00, and there was also a pre-session on 6.10.2025 for giving students information, guidance, and team allocations. Due to the timezone differences, only students from Europe managed to take part, as the sessions had to be conducted live. Teams were made up of four students and split between partners so that there were two students from Xamk and two students from a partner university forming each team. At the start there were 36 students that registered for the pilot, but only 21 manged to see it through to the end. Mostly this was due to timing conflicts.

After some initial difficulties with team allocations and student timetable conflicts, the sessions went well, with students soon rising to the challenge of running an ERP/SCM (Enterprise Resource Planning/Supply Chain Management) system in a simulated business over the four days, with an equivalent real time of approximately six months. Students were having session live and working in MS Teams breakout rooms to discuss and plan their strategies, and then run the system.

In Realgame, students are given a responsibility role in the company where they make the main decisions according to that role. The roles are purchasing, manufacturing, logistics, and a controller. Students need to work out their bill of materials and then from the orders coming into the system from customers, work out their manufacturing of products needed to fulfil those orders, purchase ordering for components and raw materials from the various suppliers, and sending out completed orders at the right time using the right kind of logistics provider at the right cost. The simulation has many variables, and can be customised by the facilitator, and also new possibilities and technologies can be introduced during the simulation. At the end of each session, teams were led through the business intelligence to analyse how well they were performing in comparison with each other.

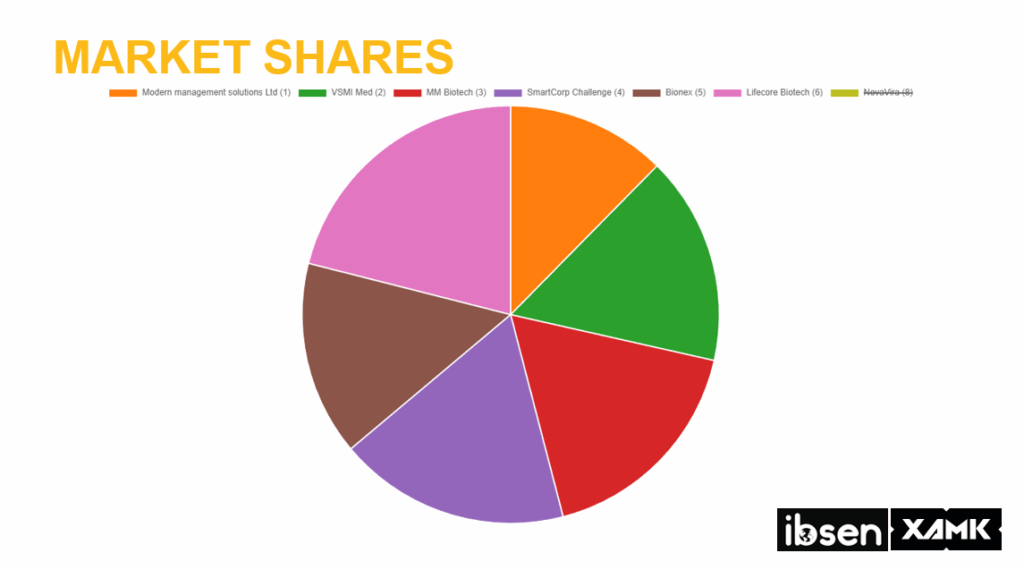

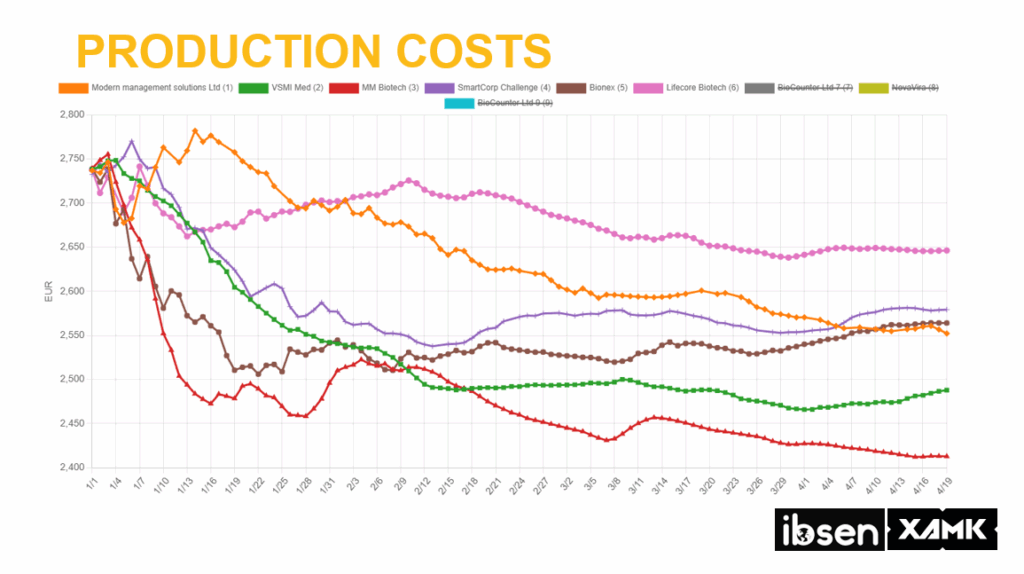

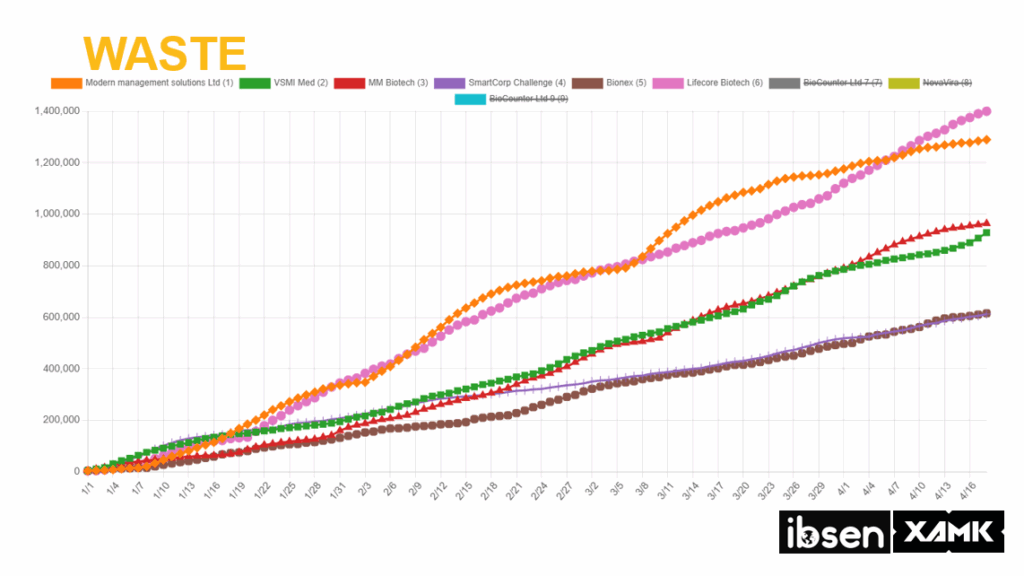

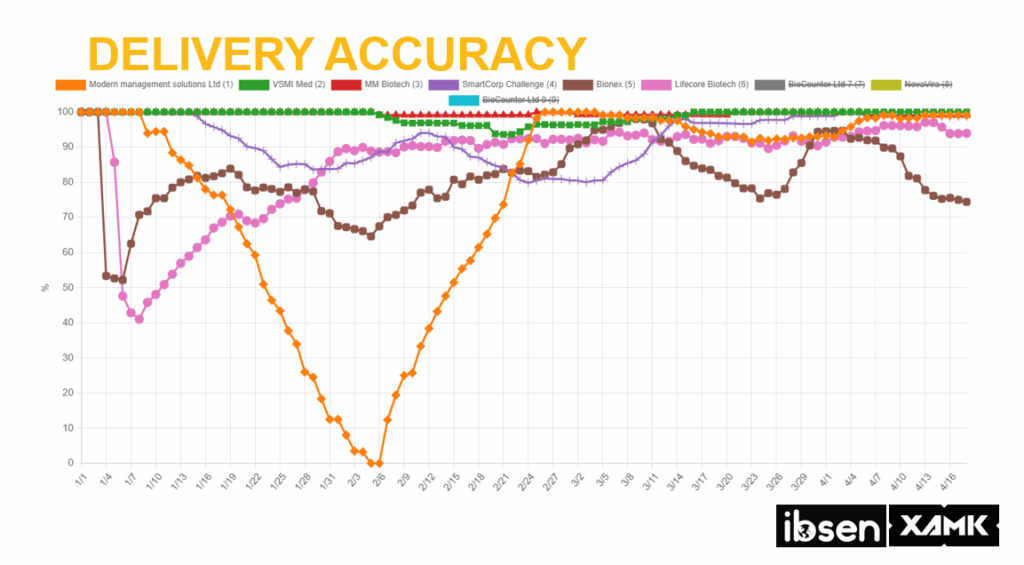

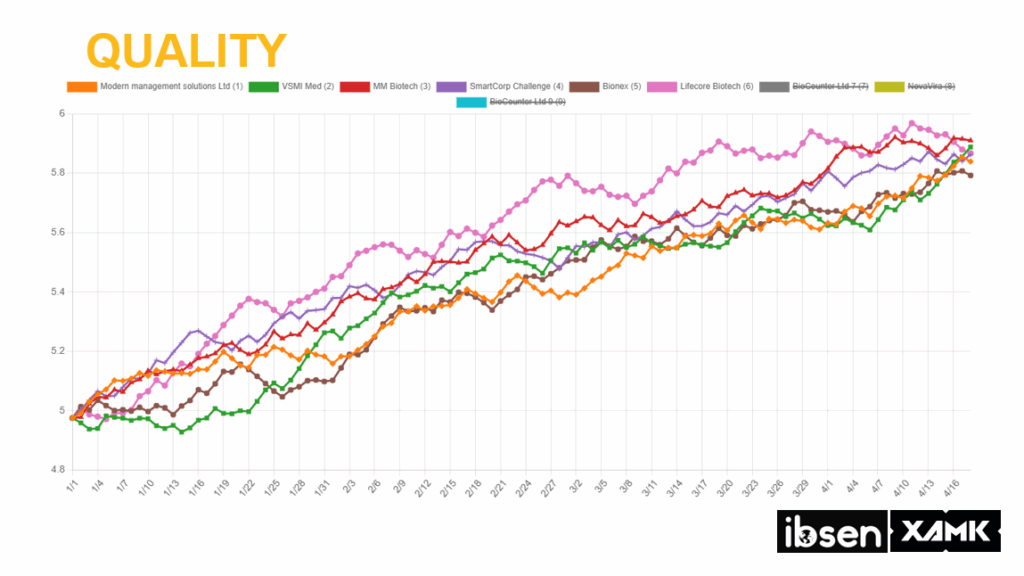

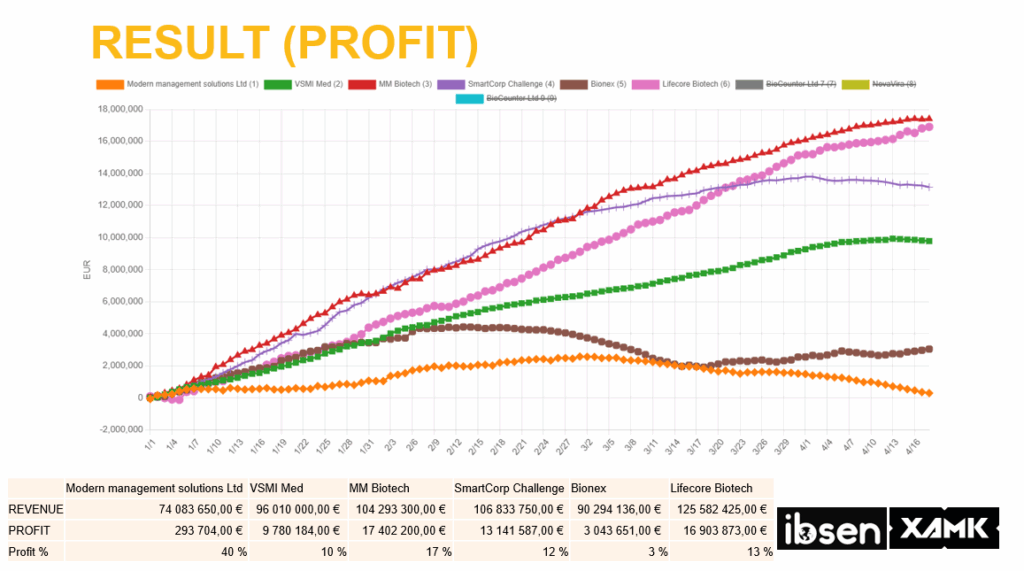

After the last simulation session, companies were analysed to see if there were any clear winners, although this is subjective in Realgame as there are several parameters for performance and to what extent the variables show whether one company is better than another. the main variables analysed in this case were: Lowered production costs; Low wastage; High delivery accuracy; Quality of service; Profit. All companies managed to improve the situation of their company from where they started out, and each maintained a fairly equal market share, and all had a profit at the end – so everyone was a winner in that respect.